.

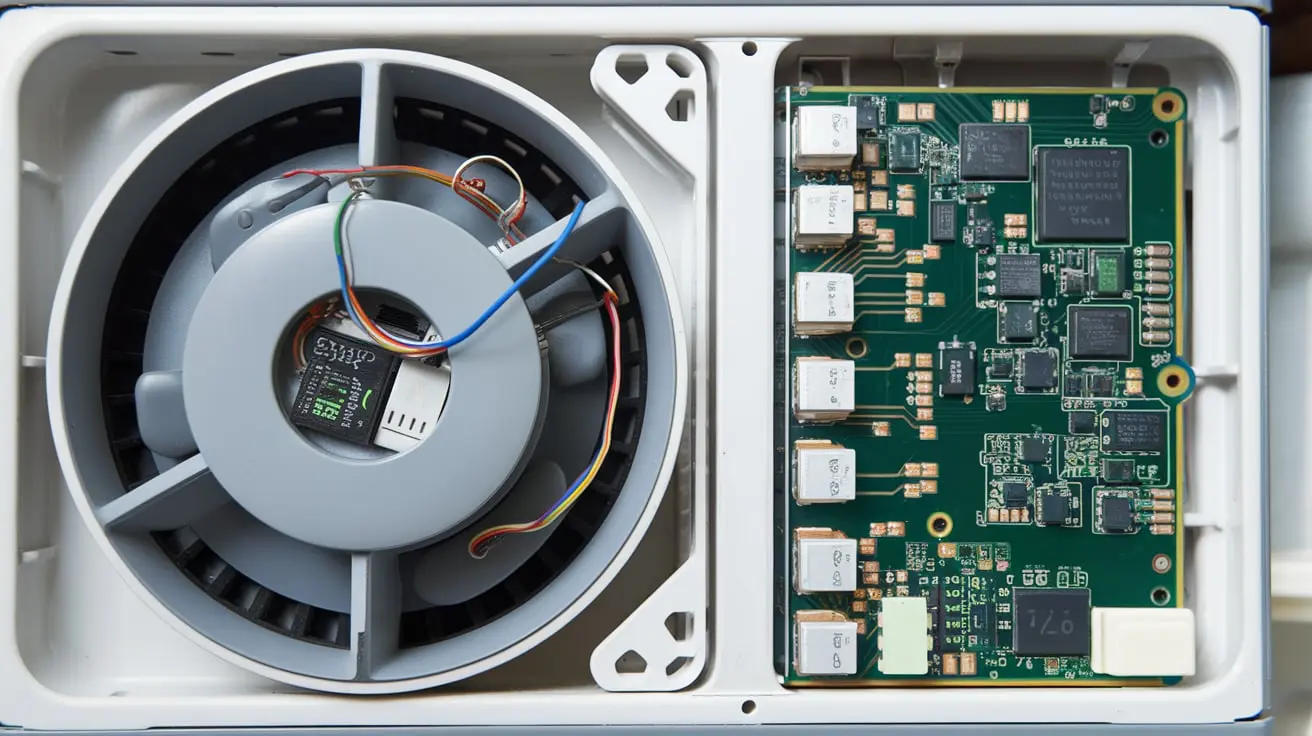

The Fujitsu ASU24RLB is a dependable air conditioning unit known for its energy efficiency and durability. However, like any machine, it can develop issues over time, particularly with its indoor motor and circuit board. Understanding these common problems can help you troubleshoot effectively and maintain the unit’s performance.

Overheating of the Indoor Motor

Overheating is one of the most common issues with the indoor motor of the Fujitsu ASU24RLB. This problem can lead to reduced efficiency and, in severe cases, motor failure.

Causes:

- Blocked Airflow: Dust, debris, and other obstructions can block the airflow, forcing the motor to work harder and overheat.

- Lack of Lubrication: Proper lubrication reduces friction within the motor. If lubrication is insufficient, the motor can overheat due to increased friction.

- Worn Bearings: Bearings support the motor’s moving parts. When they wear out, the motor struggles to function smoothly, causing it to overheat.

Solutions:

- Regular Cleaning: Ensure that the air filters and vents are clean to maintain proper airflow.

- Lubricate Bearings: Regularly lubricate the motor’s bearings to minimize friction and prevent overheating.

- Replace Worn Bearings: If the bearings are worn, replace them promptly to avoid further damage to the motor.

Circuit Board Failure

The circuit board controls the overall operation of the Fujitsu ASU24RLB. A failure in this component can disrupt the entire system, leading to various operational issues.

Causes:

- Power Surges: Sudden spikes in voltage can damage the delicate components on the circuit board.

- Moisture: Moisture can cause corrosion or short circuits on the circuit board.

- Aging Components: Over time, the components on the circuit board can degrade, leading to failure.

Solutions:

- Install a Surge Protector: Protect the circuit board from voltage spikes by using a surge protector.

- Control Humidity: Keep the unit in a dry environment and check regularly for moisture.

- Replace Aging Components: Regularly inspect the circuit board and replace any aging or failing components to prevent total failure.

Motor Making Unusual Noises

Unusual noises from the indoor motor usually indicate a problem that needs to be addressed immediately to prevent further damage.

Causes:

- Loose Parts: Over time, screws, bolts, or other components may loosen, causing vibrations and noise.

- Damaged Fan Blades: Bent or damaged fan blades can create noise as they interfere with the motor’s operation.

- Worn Bearings: Bearings that are worn out can produce grinding or squealing noises.

Solutions:

- Tighten Loose Parts: Regularly check for loose components and tighten them to reduce noise.

- Inspect and Replace Fan Blades: Examine the fan blades for any damage and replace them if necessary.

- Replace Worn Bearings: If the noise is caused by worn bearings, replace them immediately to avoid further damage.

Motor Fails to Start

When the indoor motor fails to start, it disrupts the entire cooling process. This issue is often linked to electrical problems or component failures.

Causes:

- Blown Fuse: A blown fuse can cut off power to the motor.

- Faulty Capacitor: The capacitor is essential for starting the motor. If it fails, the motor won’t start.

- Wiring Issues: Damaged or loose wires can interrupt the power supply to the motor.

Solutions:

- Check and Replace Fuses: Inspect the fuse box and replace any blown fuses.

- Test and Replace Capacitor: If the capacitor is faulty, replace it to restore motor function.

- Inspect and Repair Wiring: Examine the wiring for any damage or loose connections and repair them as needed.

Circuit Board Malfunction

A malfunctioning circuit board can cause various operational issues, from the unit not turning on to inconsistent cooling.

Causes:

- Software Bugs: The board’s software may develop bugs that cause it to malfunction.

- Component Failure: Individual components on the board can fail, leading to system-wide problems.

- Electrical Interference: External electrical interference can disrupt the board’s normal operation.

Solutions:

- Update Software: Regularly update the circuit board’s software to fix bugs and improve performance.

- Test and Replace Faulty Components: Identify and replace any failed components on the board.

- Reduce Electrical Interference: If external interference is an issue, consider shielding the unit to protect the circuit board.

Continuous Motor Operation

If the motor runs continuously without shutting off, it can lead to excessive wear and reduce the lifespan of the unit.

Causes:

- Thermostat Malfunction: A faulty thermostat may not signal the motor to shut off.

- Stuck Relay: The relay switch that controls the motor may become stuck in the “on” position.

- Short Circuit: A short circuit in the wiring can cause the motor to run continuously.

Solutions:

- Check and Recalibrate Thermostat: Ensure the thermostat is functioning correctly and recalibrate or replace it if necessary.

- Replace Relay Switch: If the relay is stuck, replace it to restore proper motor operation.

- Inspect Wiring for Shorts: Examine the wiring for any short circuits and repair them as needed.

Short Circuit on the Circuit Board

A short circuit on the circuit board can cause significant damage, leading to a complete system shutdown.

Causes:

- Moisture Exposure: Moisture can create a conductive path between components, causing a short circuit.

- Component Failure: A failed component may cause a short circuit, damaging the board.

- Improper Installation: Incorrect installation can lead to short circuits on the board.

Solutions:

- Prevent Moisture Ingress: Ensure the unit is installed in a dry area and protected from moisture.

- Replace Faulty Components: Regularly inspect the board and replace any faulty components to prevent short circuits.

- Ensure Proper Installation: Have the circuit board installed by a professional to avoid installation-related issues.

Motor Humming But Not Running

A motor that hums but doesn’t run usually indicates a mechanical or electrical issue that needs immediate attention.

Causes:

- Seized Bearings: Bearings that have locked up can prevent the motor from turning, causing it to hum instead.

- Faulty Capacitor: A faulty capacitor may not provide enough power to start the motor, leading to a humming sound.

- Mechanical Blockage: Obstructions like debris may be preventing the motor from turning.

Solutions:

- Inspect and Replace Bearings: If the bearings are seized, replace them to restore motor function.

- Test and Replace Capacitor: If the capacitor is faulty, replace it to eliminate the humming sound.

- Remove Obstructions: Check for any mechanical blockages and remove them to allow the motor to turn freely.

Loss of Circuit Board Memory

If the unit frequently loses its settings or fails to remember programming, the circuit board may be experiencing memory issues.

Causes:

- Battery Failure: Some circuit boards have a small battery that retains memory. If it fails, the settings can be lost.

- Corrupted Software: Corrupted software can cause the circuit board to lose memory.

- Power Interruptions: Frequent power interruptions can disrupt the circuit board’s ability to retain settings.

Solutions:

- Replace the Memory Battery: If the circuit board has a memory battery, replace it to prevent data loss.

- Reinstall or Update Software: Update or reinstall the software to fix any corruption issues.

- Ensure Stable Power Supply: Provide a stable power supply to the unit to prevent frequent interruptions.

Motor Vibration

Excessive vibration from the indoor motor can lead to noise and potential damage to the unit.

Causes:

- Unbalanced Fan Blades: Unbalanced fan blades can cause the motor to vibrate excessively.

- Loose Mounting: If the motor is not securely mounted, it can vibrate during operation.

- Worn Bearings: Worn-out bearings can lead to an imbalance, causing vibrations.

Solutions:

- Balance Fan Blades: Inspect the fan blades and balance them to reduce vibrations.

- Secure Motor Mounting: Tighten all mounting bolts to ensure the motor is securely in place.

- Replace Worn Bearings: If worn bearings are causing the vibration, replace them to restore smooth operation.

Conclusion

Maintaining the Fujitsu ASU24RLB requires regular checks and timely interventions. Addressing common issues with the indoor motor and circuit board can extend the unit’s lifespan and ensure it operates efficiently. If you encounter any of these problems and are unsure how to fix them, consulting a professional technician is always advisable. This proactive approach will help you avoid costly repairs and keep your air conditioning system running smoothly.The Fujitsu ASU24RLB indoor motor and circuit board require regular maintenance to prevent common issues like overheating and circuit failure.