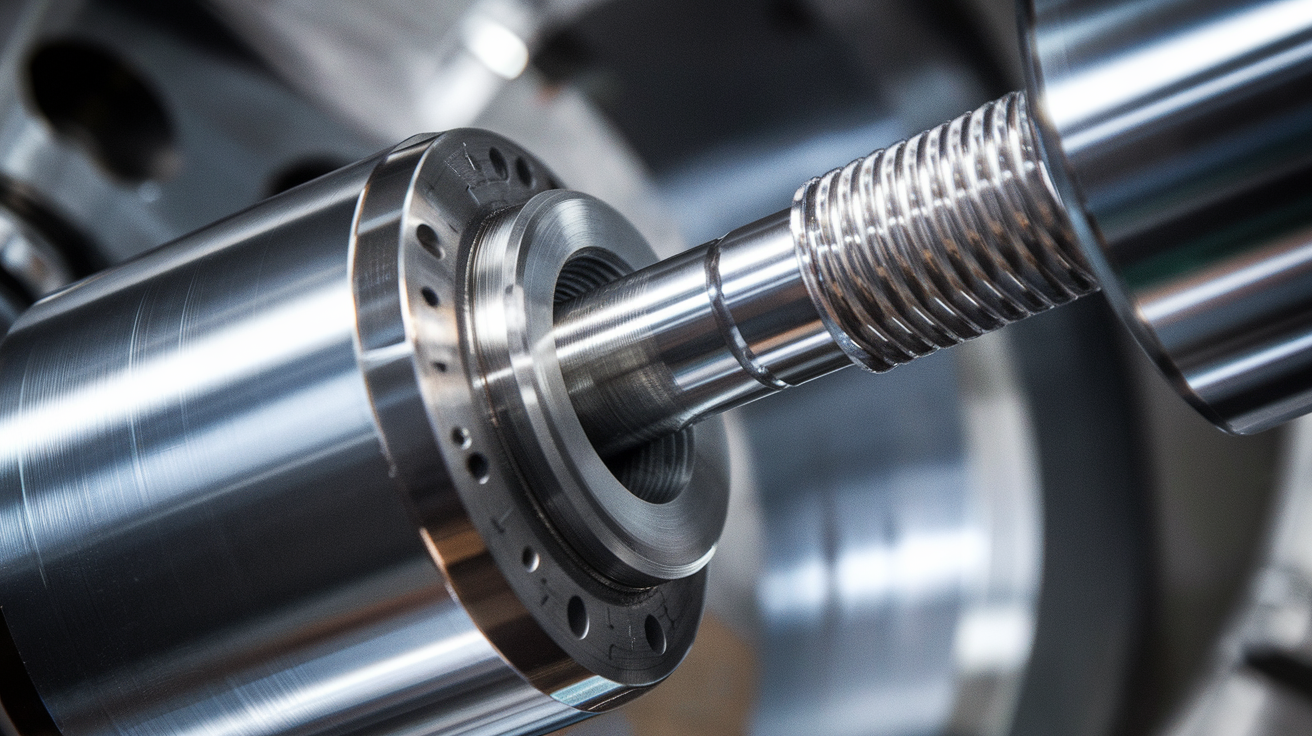

In industries that require secure and durable threading solutions, the use of free running Helicoil inserts, particularly the 1.4301 stainless steel version, offers excellent performance. Known for its strength, corrosion resistance, and reliability, this insert is ideal for numerous applications, from automotive repairs to industrial manufacturing. This article will explore the key reasons why the free running Helicoil insert 1.4301 stands out as a top choice for high-strength threading.

What is a Free Running Helicoil Insert?

A free running Helicoil insert is a coiled wire insert used to create strong internal threads in soft metals like aluminum, magnesium, or other materials prone to thread wear or damage. These inserts, when placed into tapped holes, provide a stronger, more resilient thread than the original material.

The Helicoil insert 1.4301 refers to an insert made from a specific grade of stainless steel (AISI 304), which is renowned for its excellent mechanical properties and resistance to corrosion. It is widely used in environments where durability and strength are critical.

Why Stainless Steel 1.4301?

Corrosion Resistance: Stainless steel 1.4301, commonly known as AISI 304, is highly resistant to corrosion, especially in wet or acidic environments. This makes it perfect for outdoor, marine, and chemical industry applications where exposure to corrosive elements is frequent.

Strength and Durability: The 1.4301 stainless steel grade offers superior tensile strength. When used in high-stress applications, it ensures that threads remain intact, even when subjected to heavy loads. This strength enhances the longevity of the assembly and prevents thread stripping.

Temperature Tolerance: Helicoil inserts made from 1.4301 stainless steel can withstand a wide range of temperatures, making them ideal for environments where extreme heat or cold is a factor.

Low Maintenance: Thanks to its corrosion-resistant properties, Helicoil insert 1.4301 requires little to no maintenance, even when used in harsh environments. This saves time and costs related to repairs and replacements.

Key Benefits of Using Free Running Helicoil Insert 1.4301

Improved Thread Strength

One of the primary advantages of using free running Helicoil inserts is the significant increase in thread strength. Soft materials like aluminum or magnesium tend to wear out quickly, especially under heavy loads or repeated use. The Helicoil insert, made from 1.4301 stainless steel, provides a stronger, more durable threading solution that extends the lifespan of the original material.

Resistance to Vibration and Shock

In applications where vibration and shock are frequent, standard threads can wear down or become loose over time. Free running Helicoil inserts act as a buffer, absorbing vibrations and reducing the likelihood of thread loosening. This ensures the assembly remains tight and secure, even in demanding conditions.

Corrosion Protection

If you’re working in environments where moisture, chemicals, or saltwater exposure is common, corrosion can be a major issue. The 1.4301 stainless steel Helicoil insert is designed to resist corrosion, which makes it a reliable choice for marine, automotive, and outdoor industrial applications. The insert’s ability to withstand corrosive conditions helps maintain the integrity of the threads and reduces the need for frequent replacements.

Cost-Effective in the Long Term

Although stainless steel Helicoil inserts may cost more upfront compared to other materials, they provide significant savings in the long run. Their durability means fewer repairs, replacements, or downtime, which translates to lower maintenance costs. Additionally, they reduce the risk of thread failure, which could otherwise result in expensive damage to equipment or machinery.

Versatile Applications

Free running Helicoil inserts are used in a wide range of industries, including aerospace, automotive, military, and consumer electronics. The versatility of the 1.4301 stainless steel variant makes it suitable for both high-stress mechanical applications and environments where corrosion is a major concern.

Whether you’re securing engine components, electrical housings, or machinery parts, the free running Helicoil insert 1.4301 ensures a dependable thread connection that can handle demanding tasks.